This is part 1 of a three-part series all about generative design. This part includes a complete generative design definition and explanation of how it works. Then, part 2 will explore the benefits of generative design. Lastly, part 3 will explain why you should implement an advanced CAD solution, like Creo, to integrate generative design into your organization.

When it comes to manufacturing, the goal is always to create better products faster. So, it’s essential to consistently improve, whether by using a new manufacturing method or a new design technique. However, with CAD engineering, many solutions are available thanks to modern technology. We’ll dive into one of the newest—but first, let’s cover the generative design definition.

Generative Design Definition

At the most basic level, generative design is the process of computerized programs creating and optimizing 3D models. These computer programs typically rely on other solutions, such as simulation and topology optimization, to make design decisions. Although it is often associated with additive manufacturing, with the proper constraints and programming instructions in place, generative design can be used for any type of manufacturing.

Complete generative design definition:

Generative design is a technique that leverages the power of modern 3D modeling technology and computer programing to create and optimize designs.

Get the ebook, Generative Design: Unlocking Your Product Development Potential

Explore how you can boost innovation and help your designers produce better designs in less time.

How Generative Design Works

Generative design implements the natural components of evolution, using computer algorithms for optimization. The technique was first developed in the 1970s concerning architecture, then made its way into the mechanical engineering world. Today, it typically uses CAD software to build a basic concept and then iterate alternatives.

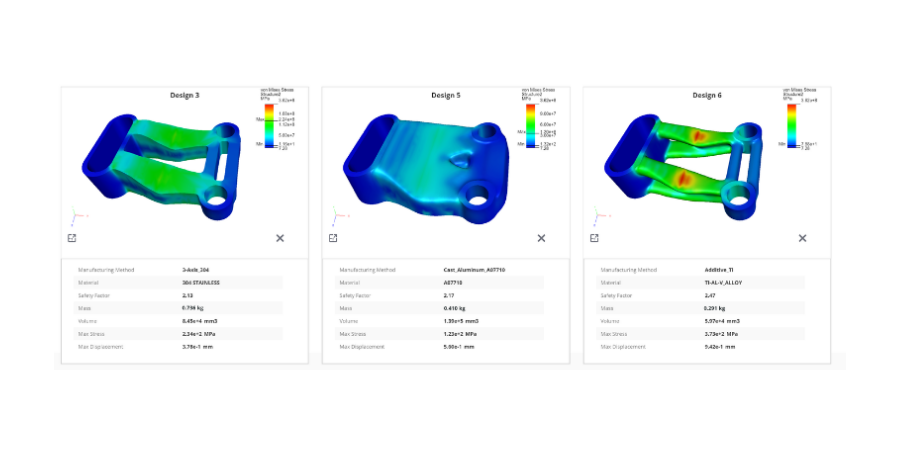

Engineers or product designers input the requirements and parameters, such as constraints, loads, etc., which are used to create and optimize each of the designs. Generative design typically goes through the following steps:

Engineers or product designers input the requirements and parameters, such as constraints, loads, etc., which are used to create and optimize each of the designs. Generative design typically goes through the following steps:

- Generation

- Analysis

- Evaluation

- Evolution

- Exploration

- Adoption

With modern technology and algorithms, generating each design iteration is an automated process. However, ultimately it is still up to the engineer to determine which option is best for their specific scenario.

While most generative design is automated, the expertise of engineers is still needed to make the final design decision.

Why Use Generative Design

Generative design revolutionizes product development by removing the need to manually create numerous design iterations. Using these modern tools allows organizations to save tons of money in terms of time and resources. By combining the power of advanced simulation tools and 3D modeling, engineers can create thousands of iterations and digitally tested them based on real-world manufacturing processes, loads, and constraints. This ultimately results in more informed decision-making, fewer iterations, and less late-stage product rework.

Generative design allows organizations to save a significant amount of money and time by reducing the need for physical prototypes and late-stage reworks.

Get Started with Generative Design with Creo

Creo makes it easy to implement generative design techniques. It includes two built-in extensions, Generative Topology Optimization (GTO) and Generative Design Extension (GDX), so Creo users can easily take advantage of everything generative design offers without purchasing or learning a new tool.

Want to learn more about what you can do with generative design? Contact us to talk to one of our experts.