This is part 2 of a three-part series all about generative design. Part 1 is our comprehensive generative design definition. This post covers generative design benefits. Then, part 3 will explain why you should implement an advanced CAD solution, like Creo, to integrate generative design into your organization.

As we covered in part 1, generative design is a technique that leverages the power of modern 3D modeling technology and computer programming to create and optimize designs. That sounds great, but what does that entail? Here, we explore the numerous benefits of this design method.

The most valuable generative design benefit is the ability to deliver innovative products to market faster.

Generative Design Benefits

One of the most powerful generative design benefits is getting your products to market faster. With ongoing optimization coupled with streamlined processes and simulation, it’s much easier to move from design to manufacturing. But that’s not all. Some other lesser-known generative design benefits include:

- Optimize legacy designs: There are plenty of times when older products are perfectly functional, but there is always room for optimization. It is relatively common practice for engineers to update designs from previous products; however, one major generative design benefit is discovering those less obvious improvements that translate into significant enhancements. This includes dramatically improving the strength of a specific part, reducing overall weight, or cutting down material use in older legacy designs.

- Improve designer efficiency: With the ever-increasing skills gap, generative design has the potential to fill holes in the workforce. Entry-level engineers with access to generative design tools and techniques can create superior parts, even if they don’t have the same level of expert knowledge as a well-seasoned engineer. In addition, once there are a myriad of designs to choose from, the right generative design solution will even be able to help less experienced designers filter through the options to select the best one.

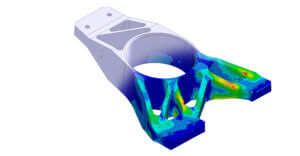

- Increase reliability: Another key generative design benefit is that you can combine it with simulation to understand how products will hold up under real-world conditions. This makes it possible to validate the durability and quality of designs without investing in a physical prototype. It also helps save costs in manufacturing and service support.

- Differentiate products: It is common to generate new designs based on existing working models. (It simply doesn’t make sense to start from square one.) However, with only slow, incremental changes to present to customers, it is easy to get stuck. Generative design allows you to break out of that rut. With multiple iterations to choose from, engineers can easily create new, high-performing parts and products that exceed requirements.

The benefits of generative design are clear. This technique can close the widening skills gap, help improve existing products, and more.

Get the ebook, Generative Design: Unlocking Your Product Development Potential

Explore how you can boost innovation and help your designers produce better designs in less time.

Creo with Generative Design: A Faster, More Reliable Approach

Creo, from PTC, has all of these features built right in. That means if you’re already a Creo user, you can reap all of the generative design benefits without purchasing or learning another tool. For manufacturing organizations looking for ways to stay competitive, implementing generative design is an excellent place to start by getting better products to market faster while using fewer resources.

Want to get started with generative design? Contact us to speak to one of our experts.