This is part 3 of a three-part series all about generative design. Part 1 is our comprehensive generative design definition. Then, part 2 covers the benefits of generative design. Finally, this post explains why you should implement an advanced CAD solution, like Creo, to integrate generative design into your organization.

Globalization is significantly increasing competition in manufacturing. It’s no secret that organizations are looking for ways to stay ahead. In many cases, this means creating more differentiated products without additional engineering power. Senior employees are retiring, and there simply aren’t enough new skilled workers to take their place. Teams need tools that help significantly increase productivity to help close this gap—and that’s where Creo generative design and generative topology optimization come in.

The manufacturing industry is bracing for a gap of two million workers within the next few years.

Get the ebook, Generative Design: Unlocking Your Product Development Potential

Explore how you can boost innovation and help your designers produce better designs in less time.

Creo Generative Design and Generative Topology Optimization

Advanced CAD solutions, like Creo, have the extensions and features you need to take advantage of all the benefits that generative design has to offer, such as:

- Requirements built into the design

- Manufacturing methods that inform designs

- Multiple concepts generated quickly

Creo Extensions

While generative design and topology optimization are often used synonymously, they actually have different functions:

- Creo generative topology optimization brings together multiple elements and relies on functional objectives, constraints, and loads to determine the best design option.

- Creo generative design evolves multiple design solutions simultaneously to then select the best possible set of solutions based on the requirements.

Here’s how these methods break down into their respective Creo extensions . . .

Creo Generative Topology Optimization (GTO)

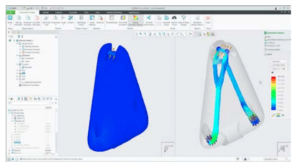

The Creo Generative Topology Optimization (GTO) extension automatically generates optimized designs based on established constraints, including material or manufacturing process. This includes designs that have all possible excess material removed without sacrificing strength. These designs have parts that are lighter, less expensive, and ultimately more efficient across the board.

Since the extension is built right into Creo, there are no issues with imports or exports, and nothing is lost in translation. While the outputs from GTO are not final, you can quickly move into other Creo solutions, like Creo Simulation Live, to run real-world simulations and then make quick modifications to get products to market quickly.

Since the extension is built right into Creo, there are no issues with imports or exports, and nothing is lost in translation. While the outputs from GTO are not final, you can quickly move into other Creo solutions, like Creo Simulation Live, to run real-world simulations and then make quick modifications to get products to market quickly.

The GTO Process

- Define the study, including designating the starting geometry body, determining which bodies should be preserved or excluded, setting constraints and local conditions, and defining the design criteria

- Run topology optimization

- Display the results (which can be static or animated)

- Use the generative design feature to save or send to GDX for more design iterations.

Creo Generative Design Extension (GDX)

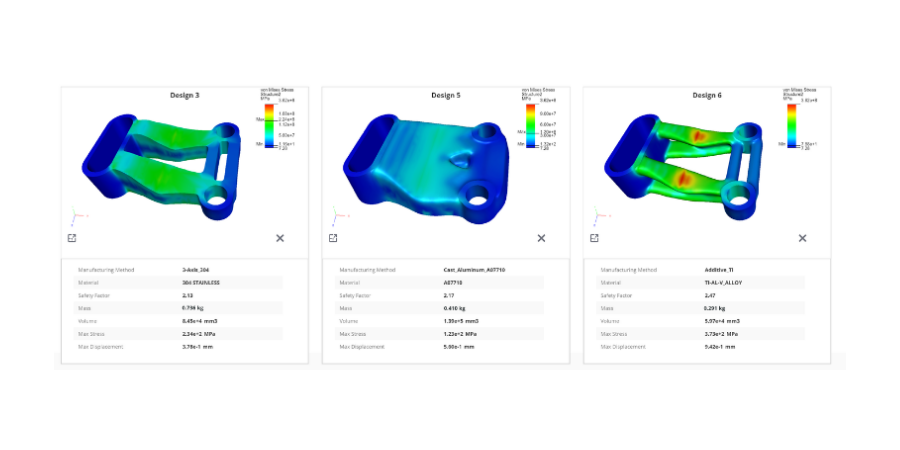

The Creo Generative Design Extension (GDX) leverages the tools and optimizations within GTO and couples them with cloud-powered computing. The basic optimization setup is similar to GTO, but instead of being limited to one design criteria, you can add multiple design criteria and materials for the study generated by GDX.

The power of cloud computing creates multiple designs simultaneously and automatically selects the top options for review. This review provides numerous design scenarios and multiple innovative geometry solutions. These optimized designs can be downloaded and used within other Creo tools for ongoing refinement and analysis.

Creo Generative Design Extension amplifies the benefits of generative topology optimization by using AI-powered cloud computing.

The GDX Process

- Define the load cases

- Specify design constraints

- Select material and design criteria

- Run the optimization

- Explore results

Creo Generative Design Extension saves you time and material costs, reduces waste, and creates better designs faster—and at an even higher level than Creo Generative Topology Optimization (GTO) alone.

Which should I use?

Depending on your specific project, you can use Creo generative design and Creo topology optimization tools separately or together. Typically, GTO is used for optimizing designs that use a defined material and manufacturing method. In contrast, GDX works best when you want to develop and compare designs using various materials and methods. This is better used for the initial generation of innovative design solutions as it allows you to quickly compare numerous scenarios.

Get Started with Creo Generative Design and Creo Generative Topology Optimization

When it comes to Creo Generative Design and Generative Topology Optimization, you can use them separately or together to improve design processes, save on materials, and get products to market faster. Each of these solutions works directly with the Creo interface, so there are no import/export or translation issues between CAD solutions. Plus, with Creo as the top CAD platform on the market, your team is sure to benefit from the other leading tools and features as well.

Ready to get started? Contact us to talk to a Creo expert.