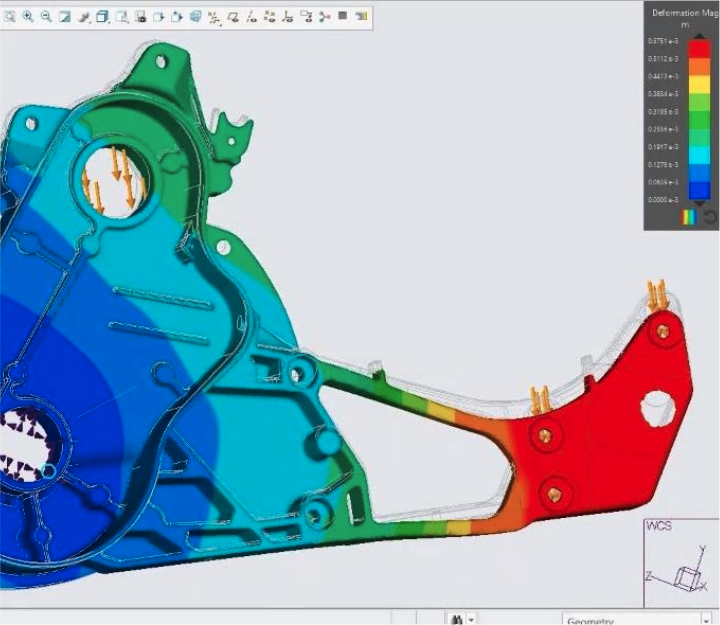

Creo Ansys Simulation puts the gold standard of simulation technologies right into the Creo environment designers and engineers are used to. It offers high-fidelity, high-accuracy simulations that guide you as you refine and validate designs across the product development process. Using Creo Ansys Simulation, users can quickly analyze products, update designs, and re-run analyses to create better products faster.

Creo Ansys Simulation provides designers and engineers with product insights earlier so teams can optimize product quality early and often within the design process.

The Creo-Ansys Partnership

Back in 2018, PTC and Ansys announced their partnership to integrate their capabilities and revolutionize CAD design. Previously, designs and simulations were completed in isolated environments, forcing complex rework processes. By bringing their capabilities together, Creo and Ansys created a solution that powers real-time simulation results during the modeling process to significantly improve designs while reducing development time and costs. Now, two products—Creo Simulation Live and Creo Ansys Simulation—provide the breadth of tools needed for teams to stay competitive in the market.

The Creo-Ansys partnership revolutionized CAD design with the first solution to combine CAD modeling and simulation in real time.

About Creo Ansys Simulation

Creo Ansys Simulation provides end-to-end simulation to analyze and understand the impact of real-world scenarios on products.

Designing with Creo Ansys Simulation

Using Creo Ansys Simulation and Creo Simulation Live, users can easily validate and optimize product designs sooner and can accomplish more in less time:

- Design validation: Using Creo Simulation Live or Creo Ansys Simulation, teams can ensure components, assemblies, and products will perform as expected in the real world. Multiphysics simulation combines structural and thermal analysis for teams to streamline optimization.

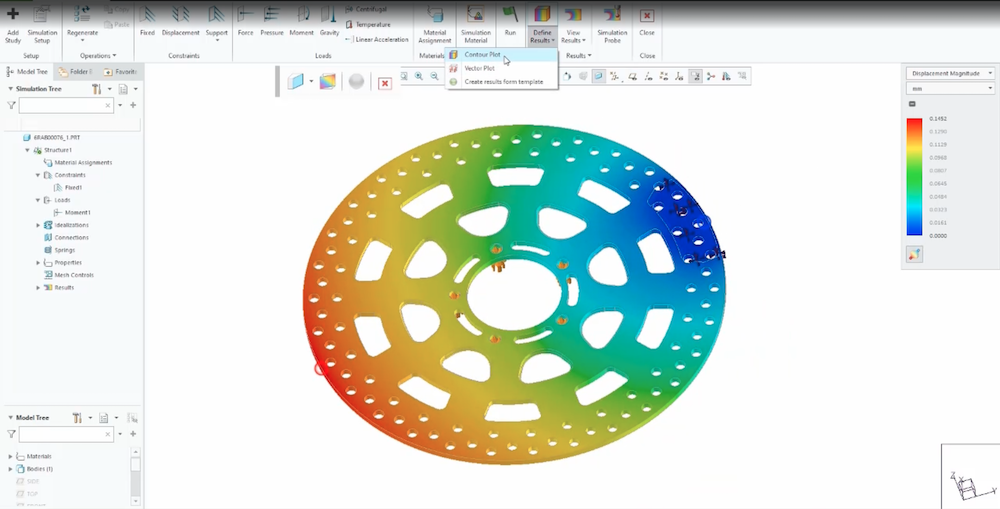

- Pre-release verification: While Creo Simulation Live can identify hot spots for optimization, further analysis should be completed prior to handoff to manufacturing. The advanced capabilities of Creo Ansys Simulation, including support for idealizations like beam, mass, shell, and spring elements, create more complete representations. Additional mesh controls, easy switching between modeling and analysis environments, and more make optimization seamless.

One study found that using simulation in the design process resulted in:

Reducing labor and prototype costs by 25-30%

Broadening design exploration by 40-60%

Creo Ansys Simulation Benefits

By using Creo Ansys Simulation you get the following benefits:

- Advanced simulation powered by Ansys

- High-fidelity and high-accuracy simulations

- All types of simulation analysis (linear static structural analysis, model structural analysis, steady-state thermal analysis, and more)

- Automatic mesh and contacts

- Support for non-linear materials and non-linear contact

- Support for masses, springs, shells, and beams

- Boundary conditions on specific geometry

Creo Ansys Simulation Features

Creo Ansys Simulation tools include a huge range of features giving you everything you need to complete your simulations:

- Combined structural and thermal simulation

- Connections

- General modeling tools

- Meshing, element types, and idealizations

- Non-linear contact

- Non-linear materials

- Process tools

- Results (both basic and advanced)

- Structural boundary conditions

- Thermal boundary conditions

Ready to Get Started with Creo Ansys Simulation?

There’s no question that running simulations early and often in the design process provides numerous benefits for designers and engineers. Between saving time, creating better products, and conserving resources, implementing simulation is a requirement for organizations looking to remain competitive in the market.