Simulation is changing the way product designers and engineers work—and for the better. Modern simulation tools make it easy to complete simulations early and often in the design process. This means more energy spent iterating and improving designs that you know will work and fewer resources wasted creating physical prototypes and waiting for simulations to finish. Creo from PTC includes a variety of tools and extensions to make it easy to implement simulation right into your existing engineering processes. Here’s everything you need to know about simulation in Creo.

Using simulation in Creo optimizes design processes, reduces costly physical prototyping, and enhances products.

Why Creo Simulation?

Understanding how your products will operate in the real world is essential to the product development process. If your team already uses Creo as your CAD platform (which they should), then implementing Creo simulation tools is easy. Teams can resolve potential design problems earlier and focus on important high-level issues. In the end, you end up with optimized products that are developed faster and with lower associated resource costs.

Understanding how your products will operate in the real world is essential to the product development process. If your team already uses Creo as your CAD platform (which they should), then implementing Creo simulation tools is easy. Teams can resolve potential design problems earlier and focus on important high-level issues. In the end, you end up with optimized products that are developed faster and with lower associated resource costs.

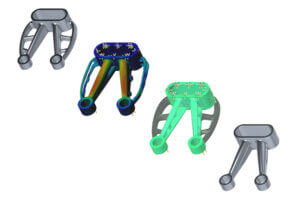

Easily complete structural, thermal, and vibration analysis and validation before you ever make your first physical part.

Creo Simulation Tools

Creo Simulation Live

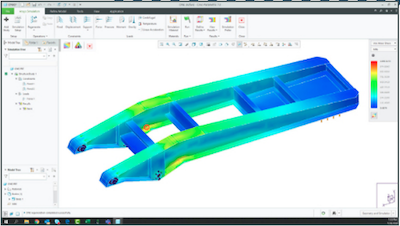

Creo Simulation Live is a groundbreaking technology that completes simulation in seconds—rather than hours—directly within the Creo environment. Simulations update dynamically in real time as users edit their designs to get instant feedback. Engineers no longer need to guess how their designs will perform in real-world conditions or wait for traditional simulations that take hours. Instead, users can iterate quickly and change their designs as needed to optimize products faster than ever before.

Users who leverage Creo Simulation Live . . .

Catch problems 65% faster.

Produce 46% fewer prototypes.

Develop 37% more innovative designs.

Creo Ansys Simulation

Using Creo Ansys Simulation provides product designers and engineers with early insight into product behavior to reduce costs and speed up time to market. The tools are integrated directly into Ansys’ advanced capabilities for steady-state thermal, linear static structural, and modal structural analysis for high-fidelity and high-accuracy simulation to support design refinement and validation. Users can save even more time by completing multiple studies per simulation model while utilizing automatic mesh and contacts.

Creo Simulation Extension

The Creo Simulation Extension is available as a stand-alone application or as an extension of Creo. It gives engineers the insights of analysis to improve their product designs through efficient iteration and optimization. The Creo Simulation Extension is specifically designed for engineers and uses the same Creo interface they are used to with standard engineering terminology, seamlessly integrating CAD and CAE data. Most importantly, results are accurate and reliable and can be easily calculated—even by those who aren’t experts in simulation.

Creo Advanced Simulation Extension

The Creo Advanced Simulation Extension builds on the capabilities of Creo Simulation to analyze and investigate complex, nonlinear impacts on product designs. Leveraging these capabilities, teams can predict the life of metal structures that can be prone to fatigue failure under cyclic loading. In addition, by investigating and analyzing these patterns, engineering can determine what types of design changes impact the endurance of these products. The Creo Advanced Simulation Extension can anticipate the behavior of anisotropic, orthotropic, hyperelastic, and composite laminates as well as model objects such as friction at assembly contact points, predefined bolts, and mass/spring idealizations.

The Creo Simulation Extension and Creo Advanced Simulation Extension are available as stand-alone applications or as extensions of your existing Creo interface.

Additional Creo Simulation Extensions

In addition to the top Creo simulation tools listed above, there are also a variety of extensions teams can utilize within the Creo interface:

- Creo Clearance and Creepage Extension for 3D electromechanical designs

- Creo EZ Tolerance Analysis Extension to visualize geometric tolerances (GTOL) and ensure all product components fit together

- Creo Fatigue Advisor Extension to analyze the load bearing of your product after repeated loading and unloading

- Creo Flow Analysis for computation fluid dynamics analysis, internal and external fluid flow analysis, and heat transfer

- Creo Human Factors Analysis Extension to investigate ergonomic and human factors issues using models

- Creo Mechanism Dynamics Option to analyze how a product will perform under real-world forces like friction and gravity

- Creo Mold Analysis Extension to simulate injection molding for plastic parts

Get Started with Creo Simulation

It’s clear that simulation is the key to improved product development and optimized operations. Teams who utilize simulation in their processes are sure to stay ahead of the competition by getting better products to market faster. If you want to stay one step ahead, it’s time to make simulation a part of your standard product development workflows.