Digital Thread Is Foundational to Digital Transformation

Digital transformation has been a trending topic for the last few years, but it’s more than just a trend. The pandemic gave the industry a much-needed push to move forward with digital transformation by exposing the existing gaps between systems and teams. As a result, top-performing companies are investing heavily in their digital transformation initiatives, supported by a digital thread foundation—and the rest of the industry is taking note.

According to a McKinsey survey, the tech decisions underpinning a successful digital transformation include smart migration to the cloud, using a common data source as a single source of truth, and moving key technology elements to a modern architecture.

However, while companies are investing in digital solutions, many are not moving toward the digital thread foundation required to achieve closed-loop manufacturing. Instead, they are optimizing individual functions and creating siloed processes, which means they can’t take advantage of the benefits of a digital thread.

To maximize impact, companies must approach digital transformation with a cross-functional approach.

Review: Closed-Loop Manufacturing Process

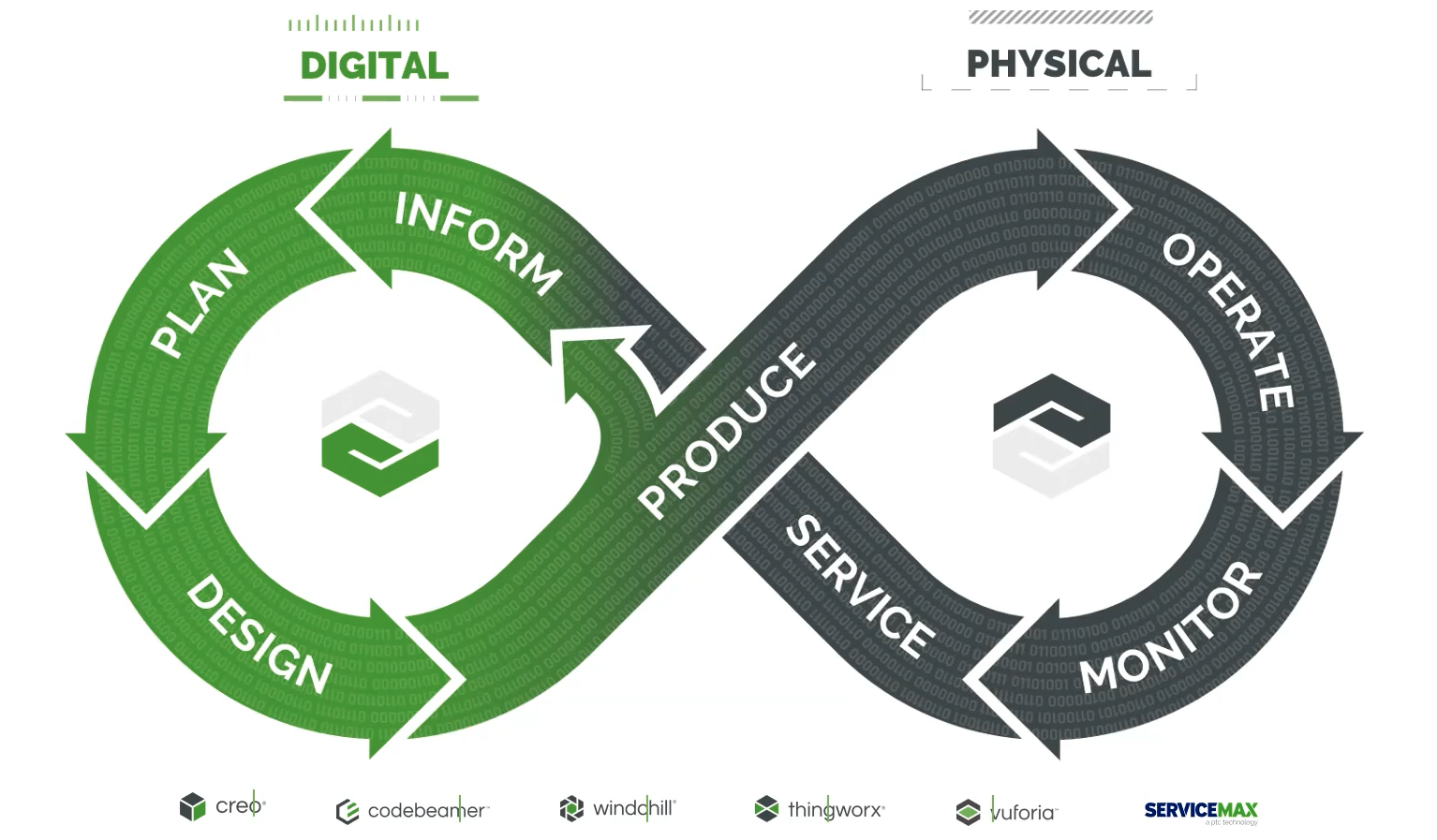

Engineers appreciate the importance of closed-loop systems when it comes to the design, creation, and ongoing manufacturing of products. Teams often want to apply what they learned during the development process to make additional changes and optimize future products. The digital thread allows this closed-loop feeding of optimized data back into the production cycle.

PTC solutions work together to create a closed-loop digital thread system encompassing every step of the development, manufacturing, and maintenance of products.

Review: Digital Thread

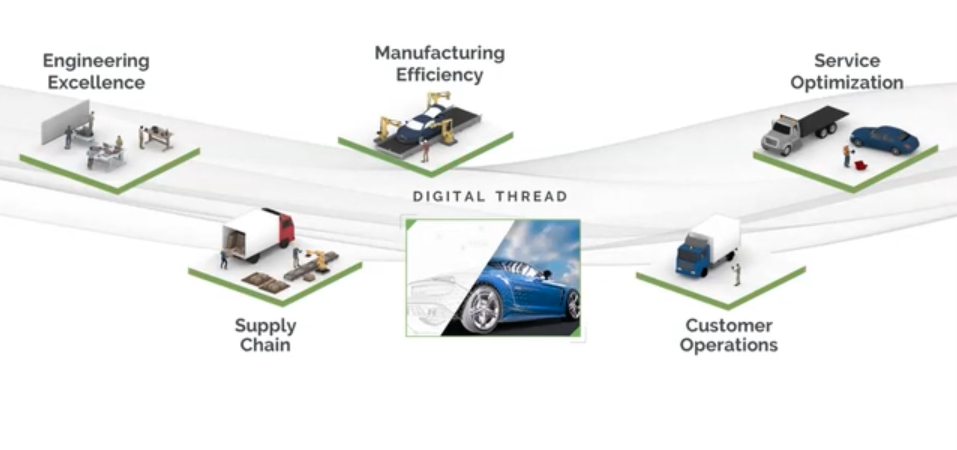

The digital thread closes the loop between the physical and digital worlds to span the entire product lifecycle. Managing product and process information ensures that information is available to the right person, at the right time, and in the right context. A digital thread solution transforms business processes to enhance the customer experience, create new business models, and improve efficiency and productivity within teams, between teams, and across the entire value chain.

Putting It Together: Creating the Closed-Loop Manufacturing Digital Thread with PTC

To create a digital thread, teams first need some form of digital design. Designs, models, assemblies, and drawings can be created in Creo. In addition to design, teams also need to collect requirements, which can be done with Codebeamer ALM. There’s a ton of data associated with these types of product designs, and teams want to access it all—CAD data, bill of materials (BOM), supplier management info, etc.—from a single location. All the data created throughout the manufacturing process can be captured and managed within Windchill PLM.

Once the data begins maturing, teams need a way to share it for improved collaboration. Data sharing can be streamlined through ThingWorx Navigate by making it easy to share content with users who just need to view it or other teams who are outside the organization.

At the end of this process, products must be serviced and maintained—that’s where Vuforia comes in. Vuforia leverages all the designs and data to create augmented reality work instructions. And for product service, ServiceMax minimizes downtime and boosts technician productivity.

Ultimately, digital thread data can inform future product development and get new and better products to market faster.

Ready to Build Your Digital Thread Foundation?

We’re one of the largest PTC resellers, so we have experts ready to help you implement the right solutions to build your digital thread foundation and support your digital transformation initiatives. If you’re interested in learning about any of the products mentioned in the video or listed above . . .