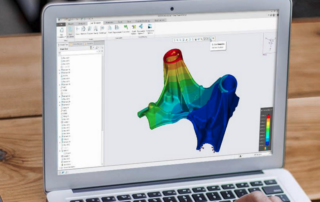

Using CAD Simulation Software to Revolutionize Product Development

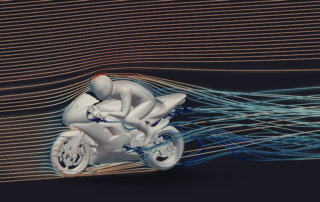

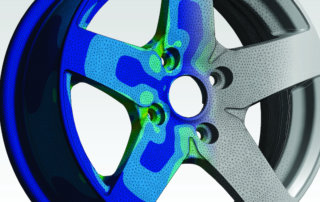

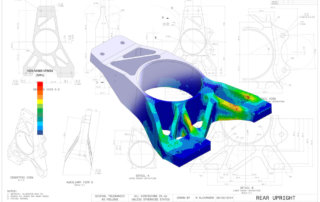

Using simulation early and often in the design process provides significant time and cost savings for teams. Taking full advantage of simulation ensures design issues are uncovered and addressed before investments are made in costly physical prototypes—and solutions can be iterative to reach the best conclusion. Powering simulation-driven design in this way requires both […]