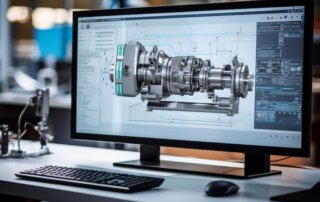

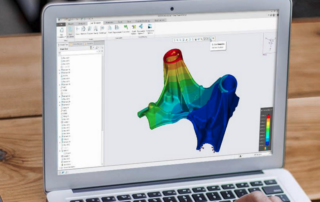

Creo Model-Based Definition: MBD in Creo

Model-based definition (MBD) is a newer approach to product development that integrates product information, such as annotations and dimensions, directly into 3D CAD Models. This makes it easier to communicate design intent, track changes, and reduce errors. […]