Creo 12 Breakdown: Creo 12 Price & Packages

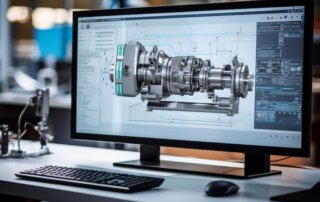

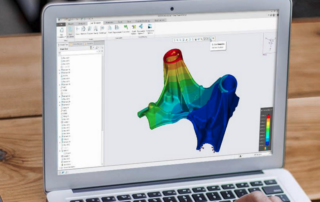

Creo 12 is here, ushering in a new era of design power, and with that, updated pricing. PTC’s updated subscription packages make it easier than ever to get the features you need, whether you’re a small team or a large enterprise. With streamlined tiers and value-packed bundles, Creo 12 ensures you’re not just keeping up—you’re […]