In manufacturing, assembly design and modeling is central to product development, showing how individual parts comes together to make a completed product. There are two main approaches to assembly design: top-down and bottom-up. Understanding the nuances between top-down vs bottom-up modeling is crucial for optimizing and enhancing product development.

Here is everything you need to know about top-down vs bottom-up modeling.

Defining Top-Down vs Bottom-Up Modeling

What is Top-Down Assembly Design?

Top-down assembly design involves creating a system that starts at the highest level and then progressively refining the details. This results in a more cohesive and integrated parts structure. Designers begin with a framework and then work to create each part and component. Top-down modeling ensures that all parts fit seamlessly and remain consistent within the design. The top-down method is particularly valuable in advanced assembly design where component interactions are critical. This methodology manages changes through component relationships and constraints, and product modifications can be made at any point. These modifications can then be managed throughout the design to ensure consistency and reduce errors.

Top-down modeling is a design methodology in which the overall structure or assembly is conceptualized and then completed by building more detailed components.

What is Bottom-Up Assembly Design?

Bottom-up assembly design is the opposite of top-down, starting with creating individual components and then assembling them into a larger system. This works better to facilitate flexibility as parts are produced separately without the constraints of an overarching structure. By working at the individual component level, designers have significant flexibility in innovating with ongoing optimization for each part without the immediate need to consider the entire system. This method is beneficial when using standardized components as it encourages the reuse of existing parts, which can reduce development time and costs. It also allows for parallel development, where different teams work on separate parts simultaneously, speeding up the development process.

Bottom-up modeling is a design approach that works by constructing a system by first developing individual components and then combining them into a larger product.

Pros and Cons of Top-Down vs Bottom-Up Modeling

Top-Down Assembly Design Pros

- Helps to maintain comprehensive control over the design process

- Components are designed for alignment with the overall project objective

- Centralized management of design changes ensures seamless adjustment across the entire assembly

Top-Down Assembly Design Cons

- Establishing and considering the overarching framework’s details is time-consuming and can cause development delays.

- Individual parts have less flexibility as they must fit within a predefined framework.

- Requires careful planning and expertise to manage all the complex interdependencies.

Bottom-Up Assembly Design Pros

- Allows for flexibility in component design as each part can be optimized without the constraints of a framework.

- Supports modular projects, which allows for the reuse of components – further saving time and resources.

- Parallel development of components speeds up the overall assembly design process.

Bottom-Up Assembly Design Cons

- Independent component creation can lead to integration issues in the final assembly.

- Designs can end up less cohesive.

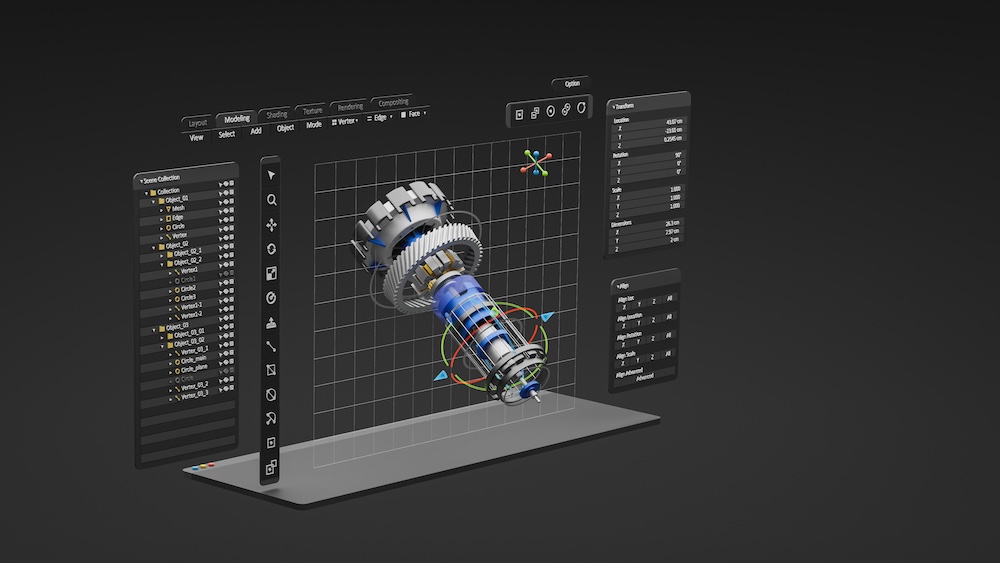

Creo: Support for Top-Down and Bottom-Up Modeling

No matter which strategy your team decides to use for assembly design – Creo has the tools you need.

Top-Down Assembly Design in Creo

Creo supports top down assembly design by allowing users to define skeleton models that guide the designs of each component. These skeletons ensure that all parts fit seamlessly within the overall structure. This is coupled with parametric design capabilities that support the setting of constraints and relationships of components to easily implement required design changes as needed throughout an entire assembly.

Bottom-Up Assembly Design in Creo

Creo also supports bottom-up modeling methods making it easy to build assemblies from individual components. It enables the creation of detailed parts that can be developed individually and then integrated into a larger system. Creo also helps facilitate the design of complex geometries and encourages component reuse, including tools to manage the relationships between parts to ensure everything fits together correctly.

Ready to Improve Assembly Design with Creo?

Creo is built to optimize processes across internal and external teams. Advanced collaboration tools streamline the entire assembly design process regardless of whether your team is pursuing a strategy of top-down design, bottom-up design, or a combination of the two.

The end result? Seamless collaboration and faster product creation.