We are currently at the junction of a new era in manufacturing and design, moving on from Industry 4.0 to 5.0. This new industrial revolution has transformative potential, building on the digital innovations of Industry 4.0, which integrated innovative technology and automation into manufacturing. Industry 5.0 takes us to the next level with a more symbiotic relationship between humans and machines. This next phase utilizes collaboration with robots alongside human workers for unprecedented efficiency and customization. Here’s everything you need to know about Industry 5.0.

What is Industry 5.0?

Industry 5.0 is the next evolutionary step in the industrial landscape, shifting from automation to more human-robot collaboration. While Industry 4.0 emphasizes smart automation and data exchange, Industry 5.0 is more of a seamless integration between humans and machines, putting the human touch back into design and product development. Many predict the introduction and use of collaborative robots, also known as cobots, powered by AI that work alongside human operators for increased manufacturing efficiency.

Industry 5.0 definition: Industry 5.0 is the next industrial revolution, focused on combining humans’ collaborative powers with AI-powered robots to improve efficiency and increase customization possibilities at every manufacturing stage.

How did we get to Industry 5.0?

The journey to Industry 5.0 begins with…

- Industry 1.0: The First Industrial Revolution began in the late 18th century and was marked by the invention of machinery powered by water and steam. During this revolution, manual labor was replaced by machinery, significantly increasing productivity.

- Industry 2.0: The Second Industrial Revolution began about 120 years later, in the early 1900s. At this time, electricity was introduced, helping make mass manufacturing and assembly lines commonplace.

- Industry 3.0: The Third Industrial Revolution, which began in the latter half of the 19th century, was fueled by the rise of electronics, information technology, and computers. It ultimately ushered in a new era of automation and digitization.

- Industry 4.0: The Fourth Industrial Revolution is debatably where we are now (but are transitioning out of). It began in the early 2000s and integrated cyber-physical systems, as well as the internet. This produced technologies like the Internet of Things (IoT) and cloud computing, which powered the creation of smart factories.

Understanding our evolution through each industrial revolution helps contextualize the transformative potential of Industry 5.0.

The Core Values of Industry 5.0

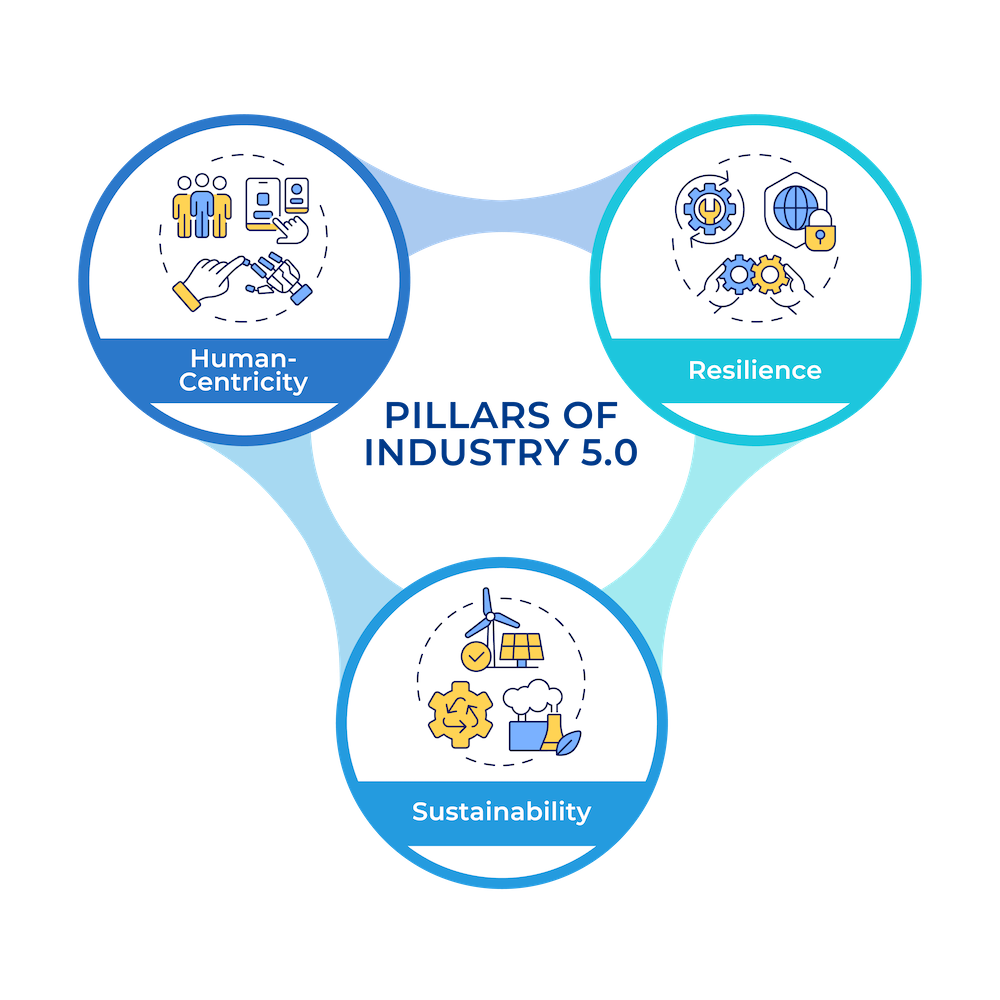

Industry 5.0 is primarily driven by three core values:

- Human-centric: In a move away from the machine automation of Industry 4.0, Industry 5.0 ushers in a new area that moves away from people being simply a resource and instead a genuine asset. This requires utilizing highly skilled technical workers to work alongside machines that complement them (rather than replace them).

- Resilience: The COVID-19 pandemic revealed far more interconnectedness than previously realized. In Industry 5.0, companies are encouraged to prioritize resiliency over traditional growth and profit goals. This will prepare more companies to anticipate and handle crises and ensure stability during more challenging times.

- Sustainability: Industry 5.0 aims to grow on existing sustainability goals and bring them to the forefront of the next revolution. More organizations are expected to actively pursue efforts to fix climate issues rather than focus on reducing the impacts of climate change. This encourages the development of circular processes to decrease the environmental effects and leave a better world for future generations.

The Key Technologies Driving Industry 5.0

The future of Industry 5.0 is largely driven by innovative enabling technologies that support a global transformation in how products are designed and manufactured.

Artificial Intelligence (AI)

AI-powered systems and tools are the backbone of Industry 5.0. These systems, often coupled with big data analytics, can learn, analyze, and make decisions. Complex algorithms enable machines to process vast volumes of data in real-time to drive diverse applications.

AI can also support predictive analysis, enabling more efficient planning. It allows teams to make proactive decisions about maintenance, significantly reducing unplanned downtime.

AI enables manufacturing organizations to process, analyze, and make decisions based on massive volumes of data to drive design and manufacturing efficiencies.

Collaborative Robots (Cobots)

AI is also used to power the next generation of robots. These machines are designed to work collaboratively alongside human workers to push past the limitations of traditional automation. By combining the power of human skills with machine capabilities, humans and robots work together to complete precise, specialized, and/or repetitive tasks.

Cobots work alongside their human counterparts to break through the limitations of traditional automation.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR significantly shift how humans interact within digital and physical environments. AR enhances the natural world by imposing information onto a physical environment through a device. This can translate to practical applications that help improve data communication or provide visual instructions.

VR is similar, but instead of superimposing data, it provides a completely immersive world. This can be used to view or manipulate virtual objects, support complete training, or even collaborate remotely with colleagues.

AR and VR provide unique digital experiences that enhance our physical world to improve communication, provide training, explore products, and more.

Get Started on Your Industry 5.0 Journey

Getting started on your Industry 5.0 journey is complex. Understanding your organization’s strategic initiatives is essential for adequately evaluating the solutions that will get you there. In many cases, moving forward with Industry 5.0 requires building upon an already established digital transformation plan.

PTC has a suite of solutions to support you wherever you are now or wherever you are headed in your journey. Their cutting-edge technologies and regular release updates put them at the forefront of Industry 5.0. From advanced computer-aided design (CAD) tools supported by simulation and generative design with Creo to robust product lifecycle management (PLM) and application lifecycle management (ALM) tools with Windchill – the PTC family has you covered.

If you’re interested in learning more about how you can supercharge your digital transformation journey to support future Industry 5.0 initiatives, contact us.