Using simulation early and often in the design process provides significant time and cost savings for teams. Taking full advantage of simulation ensures design issues are uncovered and addressed before investments are made in costly physical prototypes—and solutions can be iterative to reach the best conclusion. Powering simulation-driven design in this way requires both investing in the right CAD simulation software and allowing for shifts in your work processes.

Using CAD Simulation Software

Traditional product development processes rely on physical testing for validation and decision-making. By swapping this for simulation-driven methods powered by CAD simulation software, engineers can spend more time optimizing designs for performance, which reduces costs across the entire product development cycle.

Starting in the conceptual phase, teams can use specialized CAD simulation software to support generative design. These solutions automatically optimize design parts based on specific constraints and objectives. This strategic approach helps refine designs with data-backed decision-making to meet the quick turnaround expectations of today’s customers.

CAD simulation software makes it easier to implement simulation into the design process to create better products faster and more efficiently.

Implementing CAD Simulation Software

Choosing the right solution is one task, but the effective implementation of CAD simulation software is another. To realize the transformative properties of simulation technology, you have to do more than just use it. It requires you to adopt a fundamental shift in your organizational processes.

To be effective, simulation must be integrated early in the design process, empowering teams to check and optimize their work. This often requires integrating analysts into teams they may not have been a part of before. While it may take some adjustment, this analyst-designer collaboration ultimately provides more product insight, which increases product quality.

To fully leverage the benefits and potential of CAD simulation software, teams must be open to making significant cultural and procedural shifts.

Creo: The Ideal CAD Simulation Software

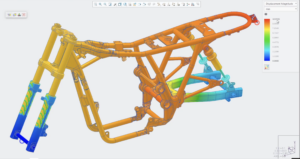

For example, Creo from PTC is a leading CAD simulation software solution that provides real-time simulation feedback directly within the design environment. This makes it easy to explore design options without having to convert files or switch between tools. Teams can easily test:

- Structural strength

- Thermal effects

- Modal frequencies

- Fluid dynamics

Teams can use Creo CAD simulation software to perform high-fidelity and functional simulations:

Teams can use Creo CAD simulation software to perform high-fidelity and functional simulations:

- Linear static structural analysis

- Model structural analysis

- Steady-state thermal analysis

These real-time CAD simulation software tools can even predict the following:

- Deformation

- Temperature distribution

- Strain

- Stress

- Vibration modes

- Resonance frequency

Ready to Get Started with CAD Simulation Software?

Simulation tools for product design have transitioned from nice-to-have to significant competitive advantage that cannot be ignored. As these advantages continue to evolve, organizations that fully leverage simulation tools will usher in a new era of innovation and productivity. Embracing the benefits of CAD simulation software will put your team at the forefront of engineering excellence.

Ready to get started with CAD simulation software? Contact us for more information and pricing.