Since it debuted on the market, the Mark Two 3D printer has been redefining what people expect from 3D printed objects.

The MarkForged machine prints plastic parts, which can be reinforced with three types of material: carbon fiber, Kevlar, and fiberglass. This allows users to create working prototypes and high-quality end-use products – a huge milestone in the quest to streamline the design process.

These frequently asked questions shed light on Mark Two printing material that you can use to reinforce 3D printed objects.

What makes the Mark Two different from other 3D printers?

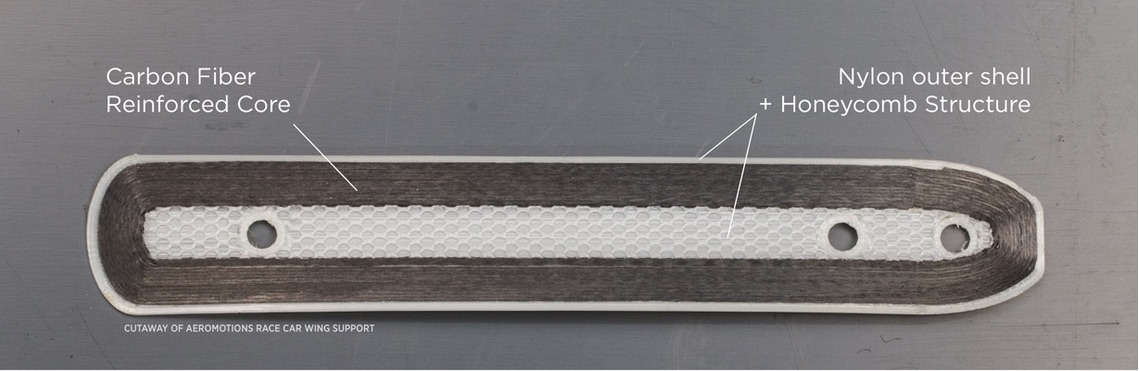

The Mark Two uses CFF™ (Composite Filament Fabrication™), a new 3D printing process, in combination with traditional fused filament fabrication (FFF). Parts made with CFF™ are reinforced by continuous strands of fibers, which are embedded in a thermoplastic matrix.

What are the advantages of a fiber reinforced part?

Fiber-reinforced composite parts have many excellent structural qualities (see “what is a composite?”). The parts printed on the Mark Two are up to 20 times stiffer and 5 times stronger than similar parts 3D printed using ABS plastic. Their strength depends on the type, orientation, and volume fraction of the reinforcing fibers.

Are the fibers in your printing material chopped or continuous?

The Mark Two uses continuous fibers.

What are the benefits of using continuous fibers in composites?

Composites made with continuous reinforcing fibers exhibit substantial increases in strength and stiffness compared to similar materials using discontinuous (chopped) fibers.

My part doesn’t require composite reinforcement. Can I print in just Nylon?

Yes. The Mark Two features a dual printhead design. One head prints using the CFF™ process, and the other prints using the FFF process. Parts may be printed by either a single head or a combination of the two.

I usually see composite parts that are made from woven sheets. Can the Mark Two print with a weave?

No. The Mark Two does not print with a weave; instead, it deposits layers of unidirectional composite in a user-defined orientation that can be specified by layer. In general, unidirectional composites have a higher strength-to-weight ratio in the preferred fiber orientation than composites made with woven fabrics.

Why are woven fabrics often used in the fabrication of composites?

Woven fabrics offer greater ease-of-use in traditional composite lay-up manufacturing processes while maintaining the desired mechanical properties.

Can I use third party materials with the Mark One?

No. The composite resin system in the CFF™ filament is optimized to work with our nylon blend. Using a 3rd party resin will not be supported and will void the warranty on the printhead.

Where can I buy carbon fiber, fiberglass or Kevlar™ composite filaments?

You can buy any compatible filaments from us via our website.

Want more information, or ready to buy?

What to learn more about this awesome machine? Give us a call at (408) 986-0200, and we’d be happy to discuss specs, set up a demo, and figure out how much time and money a composite 3D printer can save your organization. Or drop us an email here.