Digital technology continues to accelerate the transformation of our physical world. This is becoming increasingly apparent in the digital transformation of manufacturing. Things are evolving quickly from the digitization of design through the addition of digital components to the physical manufacturing process.

Integrating a Digital Thread

Organizations looking to remain competitive must implement a digital thread throughout their operations. This digital thread supports the overall digital transformation process by creating a closed loop between the digital and physical worlds, providing a single source of data truth. It has wide-ranging impacts, transforming how products are serviced, manufactured, and engineered—and ultimately helps create consistency, collaboration, and alignment across organizations.

Organizations looking to remain competitive must implement a digital thread throughout their operations. This digital thread supports the overall digital transformation process by creating a closed loop between the digital and physical worlds, providing a single source of data truth. It has wide-ranging impacts, transforming how products are serviced, manufactured, and engineered—and ultimately helps create consistency, collaboration, and alignment across organizations.

Integrating a digital thread is necessary for organizations aiming for a seamless product development process. By eliminating specific point solutions, companies can leverage data across the enterprise to improve efficiencies and increase quality.

Digital Thread Implementation Example: CAD Models

Throughout the product lifecycle, designers complete numerous processes that leverage various technologies, such as IoT, PLM, AR, etc. Each process creates feedback data from the product, all of which can be used to improve the digital design. A digital thread helps bring this data to life.

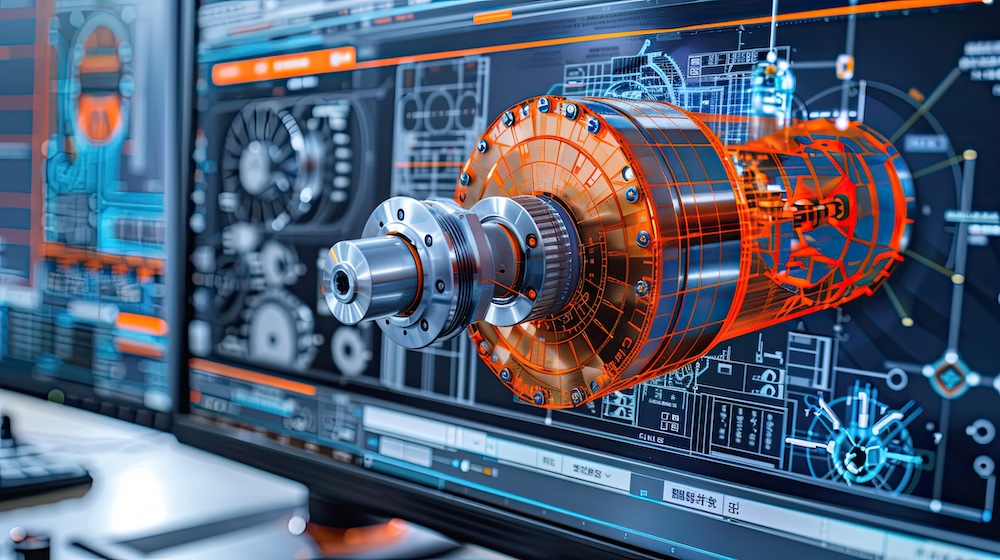

CAD models are one of the best examples of the power of the digital thread. The premise of 3D CAD modeling is that design intent is easily captured using features and constraints, which ultimately influence how the model should behave when something is changed. The associations that a digital thread provides ensure that any design changes are reflected appropriately across the model—including all associated parts/geometries—maintaining a single source of truth. This strategy is also known as a model-based definition (MBD). It provides the foundation for digital product development driven by the digital thread, which can enable companies to seamlessly transition between the conception and design phases to manufacturing and beyond.

Digital Thread Challenges & Technology Solutions

While the benefits of a digital thread are clear, implementing digital thread strategies can present a few challenges. Many of these challenges can be overcome with the latest advanced solutions from PTC.

| Challenge | Solution | Technology |

| Legacy CAD systems and other solutions may have incompatible design formats, resulting in time-consuming data conversion and migration. | Look for solutions with tools that streamline data migration, CAD consolidation, and multi-CAD collaboration. |

|

| There can be data interoperability challenges with inconsistent formats, naming conventions, and standards across departments, creating integration issues. | Use new technology implementation as a motivator for doing the data cleanup that’s often ignored, and leverage tools that allow you to work with data from other CAD solutions. | |

| The ever-growing skills gap may hold employees back from fully leveraging new CAD or MBD tools. | Provide easy-to-use, self-guided learning resources to accelerate skills development. |

|

| Sharing design data across departments and with external stakeholders can create security and IP concerns. | Make sure your solution includes access controls and that other security measures are in place. |

|

| Some engineers are resistant to change and may not want to try new technologies that move away from the traditional 2D CAD processes they are used to. | Implementing a change management strategy as part of your digital transformation initiative can help overcome this obstacle. | |

| Data quality and integrity are critical for supporting MBD and the digital thread to ensure data errors don’t move downstream. | Find a solution that makes it easy for teams to establish and access a single source of truth for design, manufacturing, and process information. | |

| Some industries have strict regulatory standards that must be followed with a digital thread implementation. | Use a digital thread solution with automated compliance workflows and implementation processes already in place. |

|

| Integrating data across design and the complete product lifecycle is necessary for a robust digital thread but can be complicated to integrate. | Search for a solution provider that has most of the tools you are looking for, and invest in the suite of products that offers the most seamless transition. |

Overcome Your Digital Thread Challenges with Help from NxRev

Overcoming the challenges faced when implementing a digital thread is not easy, but the benefits it can provide an organization are huge. Leveraging the power of CAD and MBD to implement a digital thread that supports a larger digital transformation strategy is essential to remaining competitive in the market. These capabilities will make it easier to meet customer expectations while also improving productivity with increased collaboration.

Ready to take down your digital thread challenges alongside an expert who can help you implement the latest CAD solutions? Contact us.