Time to market is dependent on time to design, which makes the choice of CAD system critical for every manufacturing company. Most CAD systems will let the engineering team create a product—eventually. The real trick is finding the solution with the best combination of features and useability. Ultimately, finding the right CAD solution will make design and modeling seamless across the entire enterprise.

If you’re currently looking to buy or upgrade your CAD solutions, you may be considering PTC Creo vs Fusion 360 from Autodesk. Both are good systems, which can make it hard to choose one, but here’s a look at some critical areas to help you decide.

Are you considering another CAD platform?

Explore our other comparisons:

Creo vs Fusion 360 Comparison Criteria:

Ease of Use

One of the essential criteria in streamlining the design process is the ease of use of the CAD system. Fusion 360 is available through any browser, so it’s accessible from anywhere at any time. It’s also available on PCs and Chromebooks. The user interface is similar across all access methods, but it is non-standard. It doesn’t follow established desktop conventions, nor does it follow established browser conventions. The unique user interface isn’t hard to understand, but even the minor differences mean it does take time to learn. It will also take some additional time to get up to speed whenever a designer approaches a task that they don’t often encounter. In addition, occasional users might find it confusing as they feel like they have to learn a new UI every time they log in.

Ease of use is a key criterion for selecting a CAD system if you have occasional or external users.

Creo is also available in a browser or through a device application, and it has a familiar user interface regardless of the access method. But for occasional tasks or infrequent users, it also has built-in guidance and workflows that help the user navigate a task to completion. This helps to improve productivity. In this instance of Creo vs Fusion 360, Creo comes out ahead.

Collaboration and Security

PTC Creo is designed for global organizations and geographically dispersed teams. Each project can have its own secure workspace, and the workspaces can be open to internal or external stakeholders, including customers and suppliers. In addition, each user can have read, write, or view privileges to each document separately, so you never have to worry about theft of your IP.

Fusion 360 has a similar approach, although not quite as robust as Creo. It does enable users to interact with designs even if they are not CAD users, which is a key capability. However, it does not have as prescriptive access rules.

Enabling non-CAD-users to access designs is crucial for modern manufacturers.

Industry Focus

Fusion 360 has a strong manufacturing focus in machining, electronics, and PCB design and layout. However, many necessary functions require the purchase and installation of specific extensions, negating any price advantage Fusion 360 brings to the table. Extensions include such seemingly necessary capabilities as machining, nesting, fabrication, data management, additive manufacturing, generative design, etc.

Creo benefits from PTC’s long history in manufacturing and has specific capabilities and expertise in a wide range of industries. Plus, while Creo does include upgrades and add-ons, the essential tools required to do most functions are included in the base package.

Industry expertise should be near the top of your list when deciding between Creo vs Fusion 360.

Creo Industry Expertise

Creo has functionality for the unique needs of manufacturing companies:

- Automotive

- Industrial machinery

- Life sciences

- Aerospace & defense

- Consumer products & retail

- Electronics & high tech

PTC also has referenceable customers in each area who will vouch for the product’s capabilities. Therefore, if your manufacturing company operates in one of these industries, you will find Creo a better choice because of the depth of the product in these industries.

Simulation

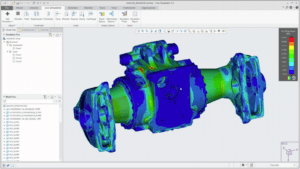

Creo includes state-of-the-art simulation capabilities that enable your team to analyze design performance without the need for physical prototypes. This helps to reduce the cost of design and reduces the overall time to market while helping to optimize product specifications.

Creo includes state-of-the-art simulation capabilities that enable your team to analyze design performance without the need for physical prototypes. This helps to reduce the cost of design and reduces the overall time to market while helping to optimize product specifications.

Fusion 360 has simulation capabilities, but using the functionality requires working with simplified models.

Model-Based Definition

Model-based definition (MBD) or model-based engineering is the hottest advance in the design world in years. MBD means capturing and conveying information about a product within the 3D model design, eliminating the need to create additional manufacturing drawings. This helps speed up market time, reduces product costs, and eliminates errors and delays.

Production workers work directly from the current model, rather than relying on redlined manufacturing or assembly drawings. As a result, product changes are communicated instantly, helping to reduce or eliminate rework and scrap.

It also helps engineers to design better products. For example, they can quickly analyze tradeoffs in design decisions, adjust component specifications, or make choices that optimize performance while meeting budget goals. And all this happens in real-time.

Model-Based design is truly the future of engineering, and no other solution has capabilities as advanced as those in Creo. When it comes to Creo vs Fusion 360, this capability alone blows Fusion 360 out of the water.

Model-based definition and model-based manufacturing will be critical needs in the near future. So don’t buy a CAD solution that can’t already support those needs.

Creo vs Fusion 360: Which is Right for Your Company?

We’ve had a long association with PTC, so we admit we may be biased, but there’s really no contest when it comes to Creo vs Fusion 360. The model-based design capabilities in Creo alone should be enough to sway your decision, but if you still have questions or would like to see a demo for yourself, contact us anytime.