Many companies today are evaluating the value of adding simulation engineering technologies to their toolbox. Simulations help prevent costly over-engineering, giving designers tools to complete rapid testing and ensure that less robust or cheaper design selections meet performance requirements and stand up to real-world usage patterns. Plus, of course, early testing and simulation help get products to market faster. That’s why many companies are evaluating Creo Simulate vs Ansys for their engineering design team.

Everybody in manufacturing knows that the earlier in the product’s cycle you identify and correct problems, the fewer headaches you endure, and the cheaper it is to correct any issues. Identifying and resolving issues while products are still in the design phase is the fastest, most affordable, and most effective point for issue resolution, so simulation software usually pays for itself quickly. But still, which is best for your company when it comes down to Creo Simulate vs Ansys? Here are a few tips to help you make the right choice.

Creo Simulate vs Ansys: Feature Breakdown

Virtual reality (VR)

Virtual reality is becoming more and more critical to manufacturing companies, playing a role in every phase of the product’s lifecycle:

- Product idea phase: VR helps designers understand how customers will interact with the product, pointing out flaws in the user interface or even the product’s usefulness.

- Design: VR helps by reducing the number of physical prototyping cycles necessary. In some cases, it can even eliminate them, replacing them entirely with simulations.

- Manufacturing: VR helps by providing routing steps and assembly instructions to workers, and during post-sales service, technicians benefit from VR guiding them through repairs or maintenance.

Each of these instances requires industrial-strength virtual reality capabilities. Fortunately, when it comes to Creo Simulate vs Ansys, there is no clear winner. Instead, both products are excellent choices.

The Digital Thread

The digital thread is becoming a critical must-have, especially for companies in regulated or semi-regulated industries such as aerospace, automotive, energy, and for many consumer and industrial products. According to PTC and industry experts such as The Data Protech Group, HCL Technologies, and ITC Infotech, the digital thread depends on PLM, 3D simulation, VR, and digital work instructions for success. With its close integration to Windchill PLM, Creo Simulate helps deliver these crucial aspects of the digital thread without necessitating complex integration projects that add cost and slow down adoption. As a result, Creo Simulate is the leader so far in our Creo Simulate vs Ansys showdown.

A close integration of PLM and simulation capabilities enables the digital thread.

Digital Twin

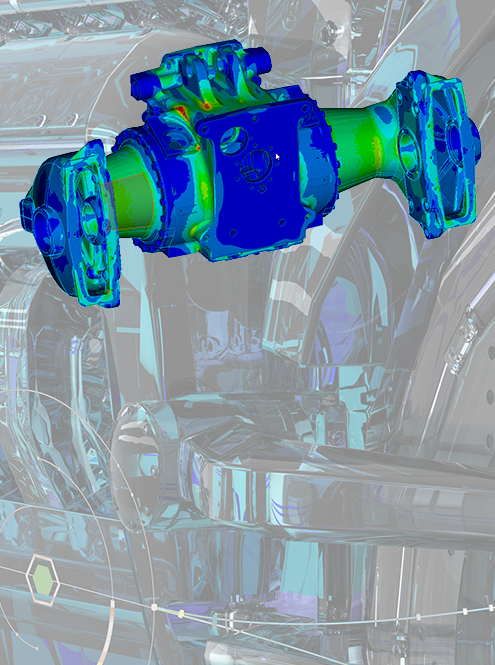

A digital thread inevitably leads to the need for a digital twin. Companies are finding that creating and maintaining a digital twin for their products helps reduce the cost of future engineering changes and required maintenance. Experts agree that PLM software is the most appropriate backbone for a digital twin since PLM is the only enterprise software solution with data covering the entire product lifecycle, from ideation to manufacturing to post-sales support. Because of its close integration with PTC Windchill, the industry’s leading PLM solution, Creo Simulate also has the edge when it comes to a company’s digital twin initiative.

A digital thread inevitably leads to the need for a digital twin. Companies are finding that creating and maintaining a digital twin for their products helps reduce the cost of future engineering changes and required maintenance. Experts agree that PLM software is the most appropriate backbone for a digital twin since PLM is the only enterprise software solution with data covering the entire product lifecycle, from ideation to manufacturing to post-sales support. Because of its close integration with PTC Windchill, the industry’s leading PLM solution, Creo Simulate also has the edge when it comes to a company’s digital twin initiative.

Industries

PTC has been a cornerstone of the manufacturing industry enterprise software space since its founding in 1985. It has a proven ability to anticipate and meet the rapidly changing needs of manufacturers in a range of industries:

- Traditional automotive

- Aerospace

- Consumer goods

- Industrial equipment

- Machinery

PTC is also a leader in making the IIoT (Industrial Internet of Things) a reality, and without the IIoT, there would be no digital thread.

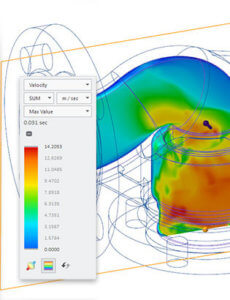

With a few exceptions, Ansys has not focused on industries as much as on specific engineering simulation needs such as:

- Flow

- Fluid management

- Acoustics

- Optics

Again, the combination of Ansys’ expertise in specific issues with PTC’s deep industry knowledge delivers the best results to most manufacturers.

Creo Simulate has deep functionality for most manufacturing industries, while Ansys has a strong capability for tricky engineering tasks like fluid and acoustic management.

Specialty Industries

Autonomous Vehicles

Ansys is an industry leader in the development, testing, and validation of safe automated driving technologies. The solution offers virtual test drives for consumers as well as engineers designing the vehicle’s systems. By simulating camera, lidar, and radar sensors, Ansys helps with testing cutting-edge scenarios and helps engineers perform HiL, MiL, and Sil tests. While Creo Simulate has other superb simulation capabilities, Ansys has made this area a specialty focus.

Commercial Aerospace vs Aerospace and Defense

The aerospace and defense industry is highly regulated. Right now, it’s under intense scrutiny as more commercial concerns enter the “space race”, an area once strictly left to government agencies.

PTC has a long and well-regarded history in the aerospace and defense industry, while Ansys has done well in commercial aerospace. As these two industry segments move closer together, the combination of Creo Simulate and Ansys will give companies the best results.

Quality

Ansys has solutions designed to simplify design analysis using tools for quality, safety, reliability, and cybersecurity. In addition, the software does model-based safety analysis and cyber security analysis, helping engineers deliver safe and secure products with quick time to market, low cost, and compliance to standards.

PTC also has a strong focus on quality. For example, recently introduced simulation-driven design capabilities show designers the cost and quality implications of their choices in components, specifications, and every aspect of the product’s design across its entire lifecycle. This capability is valuable for helping engineers design products that cost-effectively meet product specs, making Creo Simulate the winner in the Creo Simulate vs Ansys contest.

So, Which Should You Choose When It Comes to Creo Simulate vs Ansys?

Truthfully, it’s a trick question. The products complement each other so perfectly that the sum of the whole exceeds the individual components. The two companies have a strong partnership, and PTC and Ansys share a vision of helping companies improve product designs and operational procedures using Creo Simulate and Creo Ansys Simulation.

You don’t need to choose one or the other. Creo Simulate and Ansys work together seamlessly.

If you’d like to see how seamlessly the products interoperate and how the combined functionality can improve your operation, contact us today.