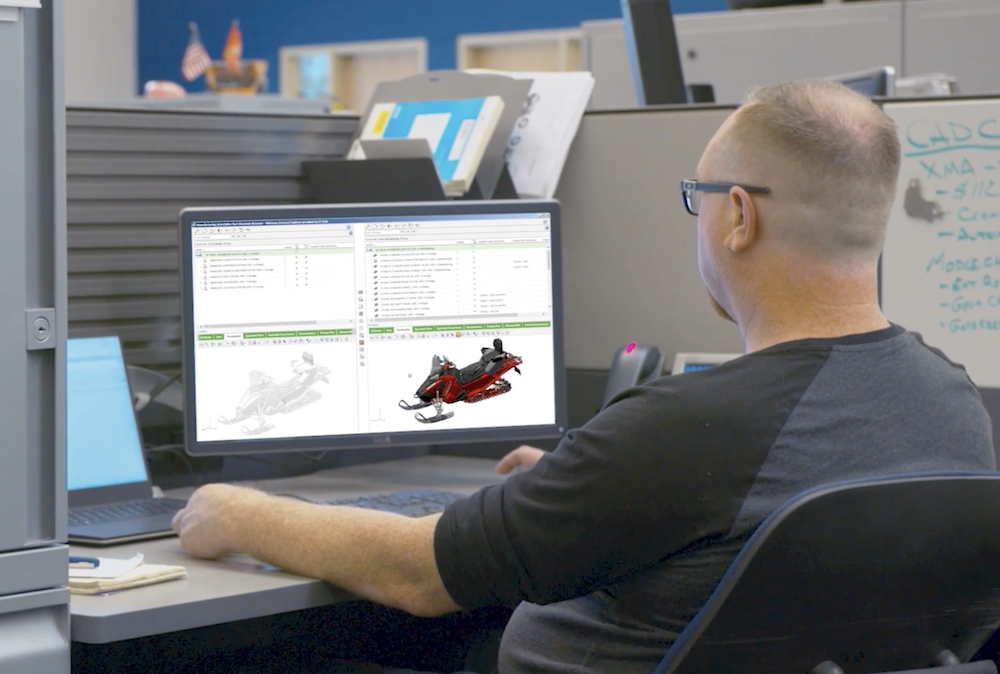

Whether you already have Windchill PLM or are looking for a new PLM solution – Windchill 12 is the solution you need. The latest enhancements are design to meet the needs to advanced engineering teams. Here are some of the latest updates to this industry-leading solution.

PTC designed Windchill 12.0 with quality in mind—at every step of your product’s lifecycle.

Want to know how Windchill stacks up against other PLM solutions?

New! OSLC Integration

PTC recognizes that products need to work together more seamlessly in today’s fast-paced environment, so they architected Windchill 12.0 to use OSLC (open services for lifecycle collaboration) for integration. Windchill now uses OSLC to integrate to other PTC products, which have also been architected to use OSLC. In addition, OSLC can integrate third-party applications such as IBM Doors NG or to Existing ERP, CRM, or SCM applications.

Using OSLC for integration simplifies using disparate products from multiple third parties.

Windchill 12 Enables a Dual Integration Strategy

Despite the efficiency and global applicability of using OSLC, PTC has not retired the existing APIs, so you can continue to operate using them until you are ready to make the switch. This means you don’t have to spend weeks or months rewriting your product integrations before you can make the switch. Instead, you can complete the change over time, as you have the resources or need to upgrade one of your existing third-party applications.

And once you have made the switch to OSLC, future upgrades will be much more straightforward, requiring less testing and few or no changes to the integration protocols.

A Focus on Quality Across Every Product and Lifecycle Phase

Manufacturing companies live and die by the quality of their products, but since most companies run several disparate systems—none of which play nicely together—it can be hard to get a cohesive picture. That’s why PTC made quality a key focus area in Windchill 12 (and the rest of its product lines as well.)

The new Windchill 12 with OSLC closes the loop between supply chain, manufacturing, engineering, and field service, giving companies the ability to uncover and correct design issues earlier in the product’s life cycle. Designing for quality helps keep product costs low, and the earlier potential problems surface, the lower the costs of corrections and redesigns.

By uncovering issues earlier, rework, and design modifications are minimized, speeding time to market and enhancing customer satisfaction. But unlike some other PLM systems, Windchill 12 also includes enhanced tracking and tracing for as-built product configurations once the product is in the field, enabling more efficient and cost-effective service and support.

New Product Extensions in Windchill 12

New extensions in Windchill 12 include Silicon Expert and HIS integration. This enhanced capability provides companies with the ability to:

- Manage part selections to minimize duplicate items

- Operate sophisticated component sourcing strategies to reduce shipping costs and stockouts

- Support better risk assessment during the design process

Enhanced Support for Product Configurations

Customers today demand unique products that meet their exact needs, but this can complicate the manufacturing process – especially when disparate systems are in use. Windchill 12 solves this problem by providing a digital thread between design and the factory floor. By enabling both design and manufacturing to operate from the same data, lead times and rework are both reduced, thereby reducing costs and increasing customer satisfaction.

Concurrent Manufacturing

Windchill 12 facilitates concurrent manufacturing with powerful BOM transformation tools that enable engineers to reconcile changes quickly and easily from base products to downstream manufacturing or plant-specific BOMs.

In effect, the PLM system becomes the repository for all a company’s essential data, while other applications, such as ERP or CRM, are data consumers, fueling themselves from the single source of truth in Windchill 12.

Concurrent manufacturing and product configuration support improves customer satisfaction, reduces cost, and speeds delivery—with less rework and fewer quality issues.

Digital First

PTC continues to lead the industry in its commitment to open standards. Windchill 12 includes many enhancements based on the OData standard. This enables companies to orchestrate their processes across multiple systems through compatibility with solutions from PTC and applications from third parties. The ability to plan and orchestrate not only day-to-day operations but also upgrades to new releases helps companies to achieve a rapid ROI on their Windchill investment and to take advantage of new functionality across the board.

Is Windchill 12.0 Right for Your Company?

Nobody but you can answer that question for sure, but if you are up-to-date on Windchill support, it makes sense to take advantage of the free upgrade, so you have access to these terrific new features. If you’re still looking for the right PLM solution, Windchill 12 is highly regarded by customers and industry analysts, so it makes sense to add Windchill to your shortlist.

In either case, if you want to learn more about the capabilities of Windchill 12.0, contact us today.